ASTM A182 F11 F22 F5 F304 F316L F53 Stainless Steel Duplex Stainless Steel Slip on Flange So RF Flange Weld Neck Flange Blind FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as

Contact Now

409 stainless steel is a ferritic stainless steel commonly used in machinery, construction and other projects. Due to the presence of austenite grains, the mechanical properties are greatly improved.

Contact Now

Nickel when added to several stainless steel alloys brings about an increase in their corrosion resistance properties. The absence of a higher content of nickel in the Stainless Steel 201 Welded Pipe led to the addition of higher contents of both manganese and nitrogen in its chemistry.

Contact Now

303 stainless steel bar: by adding a small amount of sulfur and phosphorus to make it easier to cut than 304, other properties are similar to 304.Application: petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries!Product Parameter:ProductStainless Steel BarBase materialstainless steel 200 series,300 series,400 seriesThickness0.40-5.00mmDiameter6-273mmstandardASTM A554/DIN/EN10296-2/JIS G3446,A269,A249,A270,EN10204 3.1QualitySGCC,SGCH,SGCE,SPCG,DX51Dsurface finishMill,Brush/Satin/Hairline ; MirrorFeature

Contact Now

;'////////////////+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++\]+Casting elbows reduce costs and reduce production time to a certain extent because of nearly one-time forming, which achieves the purpose of free machining or a small amount of machining.Product Parameter:Products90 Degree Cast Stainless Steel ElbowItemElbow L/R S/R,Equal Tee,Reducing Tee,Concentric Reducer,Eccentric Reducer,Cap, BendStandardASMEANSI B16.9,ANSI B16.28,ANSI B16.11,ANSI B16.25,MSS-SP-75,BS1965,BS1640DINDIN2605,DIN2615, DIN2616, DIN2617, DIN28011SGPJISB2313ENEN10253-1 EN10253-2MaterialASME

Contact Now

347h stainless steel bar is a form of stainless-steel alloy that belongs to the austenitic circle of relatives. it includes high stages of chromium, nickel, and small amounts of niobium (columbium) to enhance its resistance to corrosion and high-temperature environments.The "h" in 347h represents the high carbon content material, which affords advanced excessive-temperature power. this stainless steel grade has brilliant mechanical properties, inclusive of high tensile and yield strength.

Contact Now

Corrosion resistance.316 Stainless Steel is well-suited for building structures in marine or moist environments. The material resists oxidation, which keeps the material stronger and in good condition for longer.Pitting resistance. Unlike other types of stainless steel (such as 304), with 316 stainless steel material, building managers don’t have to worry about the formation of holes or pitting.Heat resistance. Part of the 316’s oxidation resistance stems from its resistance to heat damage.

Contact Now

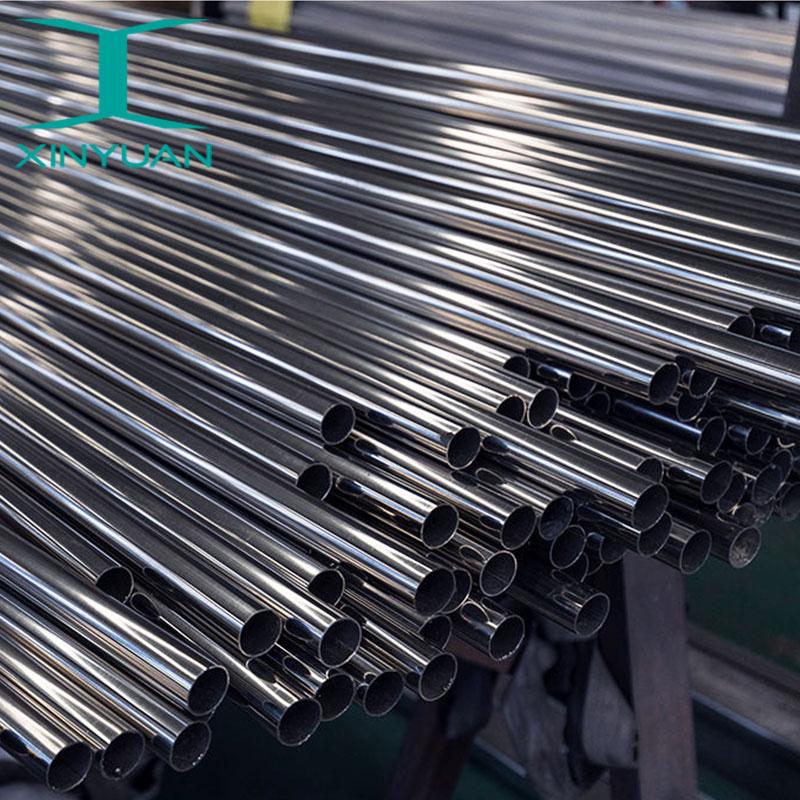

All stainless steel pipes shall be manufactured in length of 6m and may be cut to a required length accordingly to the user's requirement.Product Parameters:ItemStainless Steel Tube/PipeSteel grade200series,300 series,400series,duplexStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456,DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216,BS3605,GB13296Material304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202SurfacePolishing,annealing,pickling,brightTypehot rolled and cold rolledstainless steel round pipe/tubeSizeWall thickness1mm-150mm(SCH10-

Contact Now

Grade 316 is also primarily composed of iron, and again contains significant amounts of nickel and chromium¡ª10-14% and 16-18%, respectively¡ªand small amounts of carbon, manganese, molybdenum, and silicon.

Contact Now

Unlike mild steel the chemistry of stainless steels means the processes and methods for protecting and finishing 316 Grade Stainless Steel are vastly different to mild steels. Most surface finishes for stainless steel will be mechanically (Polishing) or chemically (Passivating) applied. The correct surface finish will have substantial impacts on the performance and appearance of your stainless steel. Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582,ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 3

Contact Now

This alloy has the following properties.1. High resistance to pitting and crevice corrosion in halide media and acidic media containing H2S2. Effective resistance to chloride ion stress corrosion cracking in practical applications3. Excellent corrosion resistance to all kinds of corrosion in the usual oxidizing and reducing environment4. Mechanical properties are improved compared to Cronifer 1925 LC-Alloy 904 L5.

Contact Now

304 stainless steel welded pipe is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish with accurate dimensions throughout length. 304 stainless steel is a high strength material with excellent corrosion resistance making it a great candidate for liquid passageways.

Contact Now

OEM ODM customized hot sale precision stainless steel threaded flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Ti

Contact Now

304L stainless steel is a variant of the lower carbon 304 stainless steel, used for welding occasions.

Contact Now

Inconel 718 PlateInconel 718 Plate is a precipitation hardening super alloy that combines high strength and oxidation resistance with superior weldability.

Contact Now

Stainless Steel 304L FlangesStainless Steel 304L Flanges has a minimum of 18% chromium and 8% nickel. Type SS 304L Blind FLanges(BLRF) has a Carbon maximum is 0.035. Stainless Steel 304L Pipe Flanges is the standard "18/8 stainless" that is commonly found in Industrial Flanges and applications. 304L Stainless Steel Blind Flange is the most versatile and widely used alloy flange. The ultimate tensile strength (UTS) of SS 304L Spectacle Blind Flange is roughly~515 Mpa, 304L having a 0.2% yield strength of~205Mpa.

Contact Now

Stainless steel attitude is a product which has two legs to form a 90 diploma angle.This product is designed for use in both structural programs and fashionable fabrication.Stainless-steel attitude’s variety of applications are extensive and might consist of trailer manufacturing, protection cages, walkways and farming gadget.

Contact Now

Popular for its corrosion resistance, stainless-steel rod is utilized in a extensive variety of applications along with the development of constructing foundations, bridges, and marine environments.we have black bright surface, and distinct materials including 201 304 304l 316 316l 2205 2507 430 420 410 so as to select.Product Parameter:ProductStainless Steel BarBase materialstainless steel 200 series,300 series,400 seriesThickness0.40-5.00mmDiameter6-273mmstandardASTM A554/DIN/EN10296-2/JIS G3446,A269,A249,A270,EN10204 3.1QualitySGCC,SGCH,SGCE,SPCG,DX51Dsurface finishMill,Brush/Satin/Hairline

Contact Now

The chemical composition of Monel400 alloy is mainly composed of 30%Cu and 65%Ni plus a small amount of Fe(1%-2%). The structure is typical monophasic austenite.

Contact Now

347 347H tp347h is a stable austenitic chromium steel that contains niobium and eliminates carbide precipitation, thus eliminating intergranular corrosion. Alloy 347 is stabilized by the addition of chromium and tantalum and provides higher creep and stress-fracture properties than alloys 304 and 304L, which can also be used for exposures requiring attention to sensitization and intergranular corrosion.

Contact Now

301 stainless steel bar is a metastable austenitic stainless steel with complete austenitic structure under the condition of full solution.

Contact Now

ASTM A182 F304 304L F316 316L Stainless Steel Socket Welding FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time

Contact Now

304L stainless steel square bar is mainly used in auto parts, hardware tools, tableware, cabinets, medical equipment, office equipment, weaving, crafts, petroleum, electronics, chemical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries!Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202

Contact Now

416 Stainless Steel Square Bar416 Stainless Steel Square Bar is a martensitic-free machining grade of stainless that can be hardened by heat treatment to achieve elevated strength and hardness. Due to its low cost and ready machinability,416 Stainless Steel Square Bar is readily used in its highly tempered state. 416 Stainless Steel Square Bar exhibits better machining characteristics than austenitic grades, however, sacrifices corrosion resistance.

Contact Now