It has good corrosion resistance in low and medium temperature hydrochloric acid.

Contact Now

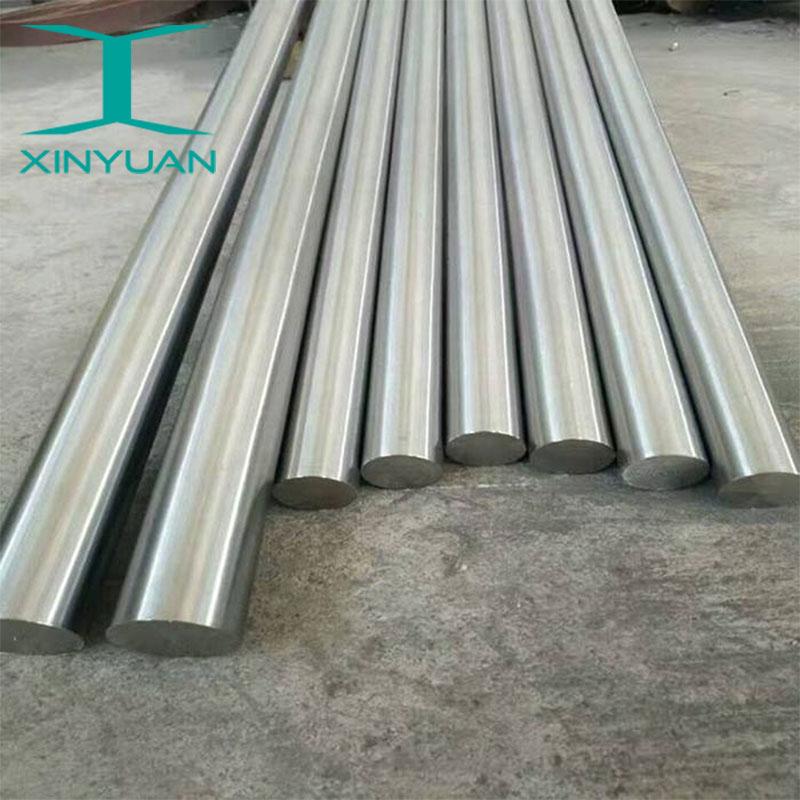

904L Stainless Steel BarNickel base corrosion resistant alloys have austenite structure. In the state of solid solution and aging treatment, there are intermetallic phases and metal carbonitrides on the austenite matrix and grain boundary of the alloy.Ni Mo alloy is mainly used under the condition of reducing medium corrosion.

Contact Now

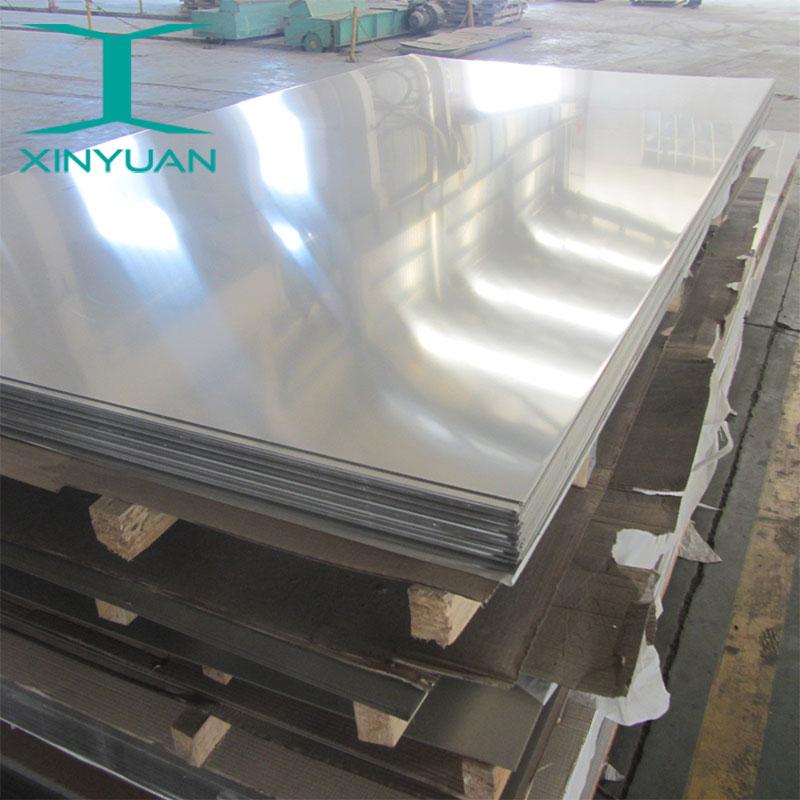

Stainless steel plate surface smooth, high plasticity, toughness and mechanical strength, acid, alkaline gas, solution and other media corrosion. It is an alloy steel that is resistant to rust, but not absolutely resistant to rust. Stainless steel plate refers to atmospheric, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosion medium corrosion of steel plate. Specification:Product Type:Stainless Steel sheet,Stainless Steel plateMaterial:201,304,304,301,304l,304N,304LN,305,309S,

Contact Now

410 Stainless Steel Checker Plate410 stainless steel contains 0.15% carbon and 13% chromium. It is a semi martensitic stainless steel. After quenching and tempering, it has high strength and toughness. It has good corrosion resistance and machining performance in a weak corrosive medium with a temperature not exceeding 30 degrees. It also has rust and corrosion resistance in wet atmosphere and fresh water, and has high thermal stability below 700 ℃.

Contact Now

Monel 400 PipeMonel 400 Pipe belongs to the copper-nickel corrosion-resistant alloy, which is the corrosion-resistant alloy with the greatest consumption, the most versatile and extremely good complete performance. Monel 400 Pipe has fantastic corrosion resistance in hydrofluoric acid and fluorine fuel medium, and additionally has exquisite corrosion resistance to warm focused lye. At the equal time, Monel 400 Pipe is resistant to corrosion from impartial solutions, water, sea water, air, natural compounds, etc.

Contact Now

321 stainless steel of Ti as a stabilizing element exists, but it is also a hot steel, in terms of high temperature is better than 316 l. 321 stainless steel in different concentration and temperature of organic acid and inorganic acid, especially in oxidizing medium has good abrasion resistance, used in the manufacture of the lining of wear resistant acid containers and equipment and pipelines.

Contact Now

s31803 Duplex stainless steel is a kind of Medium alloy stainless steel,it's PREN value is 32-33, and its corrosion resistance is between AISI 316L and 6%Mo+N austenitic stainless steel.Duplex stainless steel has the characteristics of both austenitic stainless steel and ferritic stainless steel because it has austenite + ferrite dual-phase structure, and the content of the two phase structures is basically the same. The yield strength can reach 400Mpa ~ 550MPa, which is twice that of ordinary austenitic stainless steel.

Contact Now

The alloy is resistant to high temperature corrosion properties such as oxidation and carbonization. The alloy is *** resistant to corrosion in hot corrosion areas such as sulfide environments, especially oxidation and carbonization up to 1100°C cycles. These corrosion resistance coupled with excellent mechanical properties make this alloy particularly suitable for high temperature applications.

Contact Now

Alloy 625 exhibits excellent corrosion resistance in many media.

Contact Now

This kind of material with high formability, many is given priority to with brocade alloy are more likely to be welded.

Contact Now

This alloy has the following properties.1. High resistance to pitting and crevice corrosion in halide media and acidic media containing H2S2. Effective resistance to chloride ion stress corrosion cracking in practical applications3. Excellent corrosion resistance to all kinds of corrosion in the usual oxidizing and reducing environment4. Mechanical properties are improved compared to Cronifer 1925 LC-Alloy 904 L5.

Contact Now

Copper Nickel Alloy Strip CoilCompany ProfileSince its establishment Tianjin Xinyuan Stainless Steel Co., Ltd. has been steadily seeking progress with the care and support of colleagues and customers from all walks of life, and has developed into a comprehensive enterprise integrating stainless steel material processing and sales agents.Main materials: 201, 301, 304 (0Cr18Ni9), 304L (00Cr19Ni10), 321 (1Cr18Ni9Ti), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 309S (0Cr23Ni13), 310S (0Cr25Ni20), 904L (00Cr20Ni25Mo4.5Gu) 316 , 317L, 317H, 304H, (SUS304, 321, 316, 310S, etc.).

Contact Now

600 alloy (UNS NO6600) The alloy is widely used in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubbles and condensers for fatty acid processing; Evaporator tubes, segments and spalling pans for the manufacture of sodium sulfide; And equipment for processing plants.

Contact Now

Incoloy Alloy A-286 is readily fabricated by standard procedures for stainless steel and alloys.

Contact Now

HASTELLOY C-4 alloy has exceptional resistance to wide variety of chemical process environments.

Contact Now

Hastelloy C-2000, named UNS N06200, is a nickel-chromium-molybdenum alloy. Adding a certain amount of copper to sulfuric acid, hydrofluoric acid and dilute hydrochloric acid can improve its temperature resistance. The high chromium content enables maximum resistance to oxidation chemicals and process flows contaminated by iron ions and dissolved oxygen. The alloy has excellent resistance to chloride and corrosion.

Contact Now

GH3039 is a single-phase Austenitic solid solution reinforced alloy with moderate thermal strength and good thermal fatigue properties below 800℃ and good oxidation resistance below 1000℃. Long-term use of stable structure, but also has good cold formability and welding performance. Suitable for aero engine combustion chamber and afterburner parts used for a long time below 850℃.

Contact Now

Hastelloy C-2000 Hastelloy C-2000, an optimized alloy developed to expand the application range of materials, began with the conceptual idea of adding copper to an already well-established Ni-Cr-Mo alloy. Since it entered the market in late 1995, it has continued to receive great acclaim from the market, thanks to its inherent versatility. The technical innovation not only improves the resistance of the alloy to water corrosion, but also expands the overall application range of Ni-Cr-Mo family alloys.

Contact Now

The chemical composition of Monel400 alloy is mainly composed of 30%Cu and 65%Ni plus a small amount of Fe(1%-2%). The structure is typical monophasic austenite.

Contact Now

ApplicationThe softened and annealed low carbon alloy 625 is widely used in the chemical process industry.

Contact Now

DIN 2.4375/MONEL K-500/UNS N05500 Alloy Steel Plate TypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcMonel: Monel 400/K500/R405,etcNitronic 40/50/60/75

Contact Now

Alloy B-2 is a nickel-molybdenum alloy with significant resistance to reducing environments, such as hydrogen chloride gas and sulphuric, acetic and phosphoric acids. Hastelloy® B-2 provides resistance to pure sulphuric acid and a number of non-oxidizing acids. The alloy should not be used in oxidizing media or where oxidizing contaminants are available in reducing media.

Contact Now

GH3128(GH128) Application field· Aero engine combustion chamber flame cylinder, afterburner shell and regulating plate· Structural components of gas turbine combustion chamber· Turbine engine combustion chamber components· Afterburner componentsGH4169 Application field· Main combustion chamber and afterburner of aviation engine· Welded structural parts of aeroengine· Engine mounting edge and conduit· Guide blade partsTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery

Contact Now

Inconel 617 corrosion and heat resistance.Inconel 617 alloy has good corrosion resistance in thermally corrosive areas such as sulfide environments, especially oxidizing and carbonizing environments that cycle up to 1100°C.

Contact Now